The 4HG1 engine is a four-cylinder diesel engine that was developed by Isuzu, a Japanese manufacturer of commercial vehicles and diesel engines. The 4HG1 engine belongs to the H-series of Isuzu engines, which have a displacement range of 4.3 to 5.2 liters. The 4HG1 engine has a bore of 115 mm and a stroke of 110 mm, resulting in a displacement of 4.57 liters. The engine features a direct injection system, a swirl chamber, and a turbocharger. The engine produces a maximum power of 140 PS (103 kW) at 3,200 rpm and a maximum torque of 333 Nm at 2,000 rpm. The engine is designed to be reliable, durable, and fuel-efficient, making it suitable for various applications such as trucks, buses, and industrial equipment.

Features and Benefits of the 4HG1 Engine

The 4HG1 engine has several features and benefits that make it a reliable and durable diesel engine. Some of these are:

- Direct injection system: The engine uses a direct injection system, which injects fuel directly into the combustion chamber, resulting in better fuel atomization, higher compression ratio, and lower emissions. The engine also uses a Bosch VE-type distributor injection pump, which provides precise fuel delivery and timing control.

- Swirl chamber: The engine has a swirl chamber, which is a pre-combustion chamber that creates a swirling motion of air and fuel mixture, enhancing the combustion efficiency and reducing the ignition delay. The swirl chamber also helps to reduce the engine noise and vibration.

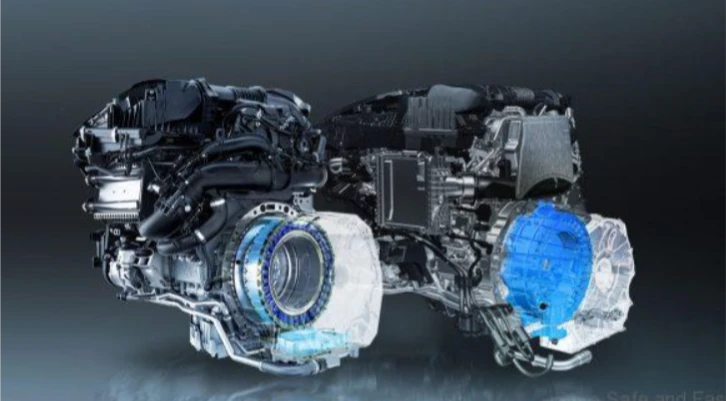

- Turbocharger: The engine is equipped with a turbocharger, which is a device that uses the exhaust gas to drive a turbine, which in turn drives a compressor that forces more air into the intake manifold, increasing the engine power and torque. The turbocharger also improves the engine performance at high altitudes and reduces the fuel consumption and emissions.

- Water-cooled EGR system: The engine has a water-cooled exhaust gas recirculation (EGR) system, which recirculates a portion of the exhaust gas back into the intake manifold, lowering the combustion temperature and reducing the formation of nitrogen oxides (NOx), one of the main pollutants from diesel engines. The EGR system also has a water-cooled EGR cooler, which cools down the recirculated exhaust gas, preventing the engine from overheating and improving the EGR efficiency.

- Intercooler: The engine has an intercooler, which is a heat exchanger that cools down the compressed air from the turbocharger, increasing the air density and oxygen content, and enhancing the engine power and efficiency. The intercooler also reduces the engine knock and detonation, and extends the engine life.

Characteristics of the 4HG1 Engine

The following table summarizes the main characteristics of the 4HG1 engine:

| Item | Specification |

|---|---|

| Engine type | Four-cylinder, four-stroke, water-cooled, turbocharged, direct injection diesel engine |

| Displacement | 4.57 liters |

| Bore x stroke | 115 mm x 110 mm |

| Compression ratio | 18.0:1 |

| Maximum power | 140 PS (103 kW) at 3,200 rpm |

| Maximum torque | 333 Nm at 2,000 rpm |

| Fuel system | Bosch VE-type distributor injection pump |

| Injection nozzle | Throttle type |

| Injection pressure | 17.5 MPa |

| Injection timing | 8 degrees BTDC |

| Valve mechanism | Overhead valve (OHV) |

| Valve arrangement | Intake-exhaust-exhaust-intake |

| Valve clearance (cold) | Intake: 0.40 mm, Exhaust: 0.50 mm |

| Firing order | 1-3-4-2 |

| Lubrication system | Forced feed by trochoid pump |

| Oil capacity | 13.5 liters |

| Cooling system | Pressurized water cooling by centrifugal pump |

| Coolant capacity | 15.5 liters |

| Air intake system | Turbocharger with intercooler |

| Exhaust system | Water-cooled EGR system with EGR cooler |

Frequently Asked Questions

What are the applications of the 4HG1 engine?

The 4HG1 engine is mainly used for medium-duty trucks and buses, such as the Isuzu N-Series and F-Series. The engine is also used for industrial equipment, such as generators, forklifts, and excavators.

What are the advantages of the 4HG1 engine over other diesel engines?

The 4HG1 engine has several advantages over other diesel engines, such as:

- Higher power and torque output, thanks to the turbocharger and intercooler

- Lower fuel consumption and emissions, thanks to the direct injection system and EGR system

- Longer engine life and lower maintenance costs, thanks to the robust design and durable materials

- Better performance and reliability, thanks to the advanced technology and quality control

What are the common problems and solutions of the 4HG1 engine?

The 4HG1 engine is generally a reliable and durable engine, but like any other engine, it may encounter some problems and issues. Some of the common problems and solutions of the 4HG1 engine are:

- Low power or poor acceleration: This may be caused by a faulty turbocharger, a clogged air filter, a dirty fuel filter, a worn injection pump, or a leaking intake or exhaust manifold. The solution is to check and replace or repair the faulty or damaged parts, and to clean or replace the filters.

- High fuel consumption or black smoke: This may be caused by a faulty EGR valve, a stuck EGR cooler, a leaking injector nozzle, a misadjusted injection timing, or a low compression pressure. The solution is to check and replace or repair the faulty or damaged parts, and to adjust the injection timing or compression pressure.

- Overheating or coolant loss: This may be caused by a faulty thermostat, a clogged radiator, a leaking water pump, a cracked cylinder head, or a blown head gasket. The solution is to check and replace or repair the faulty or damaged parts, and to refill the coolant level.

- Engine noise or vibration: This may be caused by a loose or broken belt, a worn or damaged pulley, a loose or broken flywheel, a worn or damaged crankshaft, or a loose or broken engine mount. The solution is to check and tighten or replace the faulty or damaged parts, and to balance the engine.

How to maintain the 4HG1 engine?

The 4HG1 engine requires regular maintenance and service to keep it in good condition and performance. Some of the maintenance and service items are:

- Oil and oil filter: The oil and oil filter should be changed every 10,000 km or 6 months, whichever comes first. The recommended oil grade is API CF-4 or higher, and the recommended oil viscosity is SAE 15W-40 or 20W-50, depending on the ambient temperature. The oil capacity is 13.5 liters, and the oil filter capacity is 0.5 liters.

- Fuel filter: The fuel filter should be replaced every 20,000 km or 12 months, whichever comes first. The fuel filter is located on the right side of the engine, near the injection pump. The fuel filter should be primed after replacement to remove any air from the fuel system.

- Air filter: The air filter should be cleaned every 5,000 km or 3 months, whichever comes first, and replaced every 40,000 km or 24 months, whichever comes first. The air filter is located on the left side of the engine, near the turbocharger. The air filter should be cleaned by blowing compressed air from the inside to the outside, and replaced if damaged or excessively dirty.

- Coolant: The coolant should be checked every 5,000 km or 3 months, whichever comes first, and replaced every 40,000 km or 24 months, whichever comes first. The coolant should be a mixture of ethylene glycol and water, with a ratio of 50:50. The coolant capacity is 15.5 liters, and the coolant level should be between the F and L marks on the coolant reservoir. The coolant should be replaced by draining the old coolant from the radiator drain plug and the engine block drain plug, and refilling the new coolant from the radiator filler cap and the coolant reservoir.

- Valve clearance: The valve clearance should be adjusted every 20,000 km or 12 months, whichever comes first. The valve clearance is 0.40 mm for the intake valves and 0.50 mm for the exhaust valves, when the engine is cold. The valve clearance should be adjusted by loosening the lock nut and turning the adjusting screw, using a feeler gauge and a wrench. The valve arrangement is intake-exhaust-exhaust-intake, and the firing order is 1-3-4-2.

How to troubleshoot the 4HG1 engine?

The 4HG1 engine has a self-diagnostic system, which can detect and store the trouble codes of the engine control system. The trouble codes can be read by using a scan tool or a jumper wire, and can be cleared by disconnecting the battery terminal or using a scan tool.

How to improve the performance of the 4HG1 engine?

The 4HG1 engine is already a powerful and efficient engine, but there are some ways to improve its performance and output. Some of the ways to improve the performance of the 4HG1 engine are:

- Upgrade the turbocharger: The turbocharger can be upgraded to a larger or more advanced model, which can increase the boost pressure and airflow, and enhance the engine power and torque. However, upgrading the turbocharger may also require upgrading the intercooler, the fuel system, the exhaust system, and the engine management system, to cope with the increased stress and heat.

- Install a performance chip: A performance chip is a device that modifies the engine control unit (ECU) settings, such as the fuel injection, the ignition timing, the boost pressure, and the air-fuel ratio, to optimize the engine performance and efficiency. A performance chip can increase the engine power and torque, and reduce the fuel consumption and emissions. However, installing a performance chip may also affect the engine warranty and reliability, and may require regular tuning and maintenance.

- Replace the air filter: The air filter can be replaced with a high-flow or performance air filter, which can improve the airflow and oxygen content, and enhance the engine power and efficiency. A high-flow or performance air filter can also extend the engine life and reduce the maintenance costs, as it can filter out more dust and debris. However, replacing the air filter may also require adjusting the fuel system and the ECU settings, to match the increased airflow and oxygen content.

- Replace the exhaust system: The exhaust system can be replaced with a performance or free-flow exhaust system, which can reduce the back pressure and the exhaust gas temperature, and enhance the engine power and torque. A performance or free-flow exhaust system can also improve the engine sound and appearance, and reduce the weight and the heat transfer. However, replacing the exhaust system may also require upgrading the turbocharger and the ECU settings, to match the reduced back pressure and exhaust gas temperature.